The director stands on a wet Shibuya sidewalk, gesturing toward a light that needs to move exactly three feet to the left to catch the reflection on a Bentley’s hood. In London or Los Angeles, this is a thirty-second adjustment. In Tokyo, the local production coordinator goes silent. The owner of the neighboring shop is already stepping out of his door. The officer from the nearby koban (police box) has stopped his bicycle and is watching the crew.

The “quick adjustment” has just triggered a structural halt. To the global crew, the hesitation feels like “Japanese bureaucracy” or a “lack of can-do attitude.” To the Japanese stakeholders, the director’s request is a breach of contract. The lighting plan was submitted, reviewed, and approved by the building association, the ward office, and the police weeks ago. Moving that light three feet is not a “creative tweak”; it is an unsanctioned deviation that shifts the liability profile of the entire shoot.

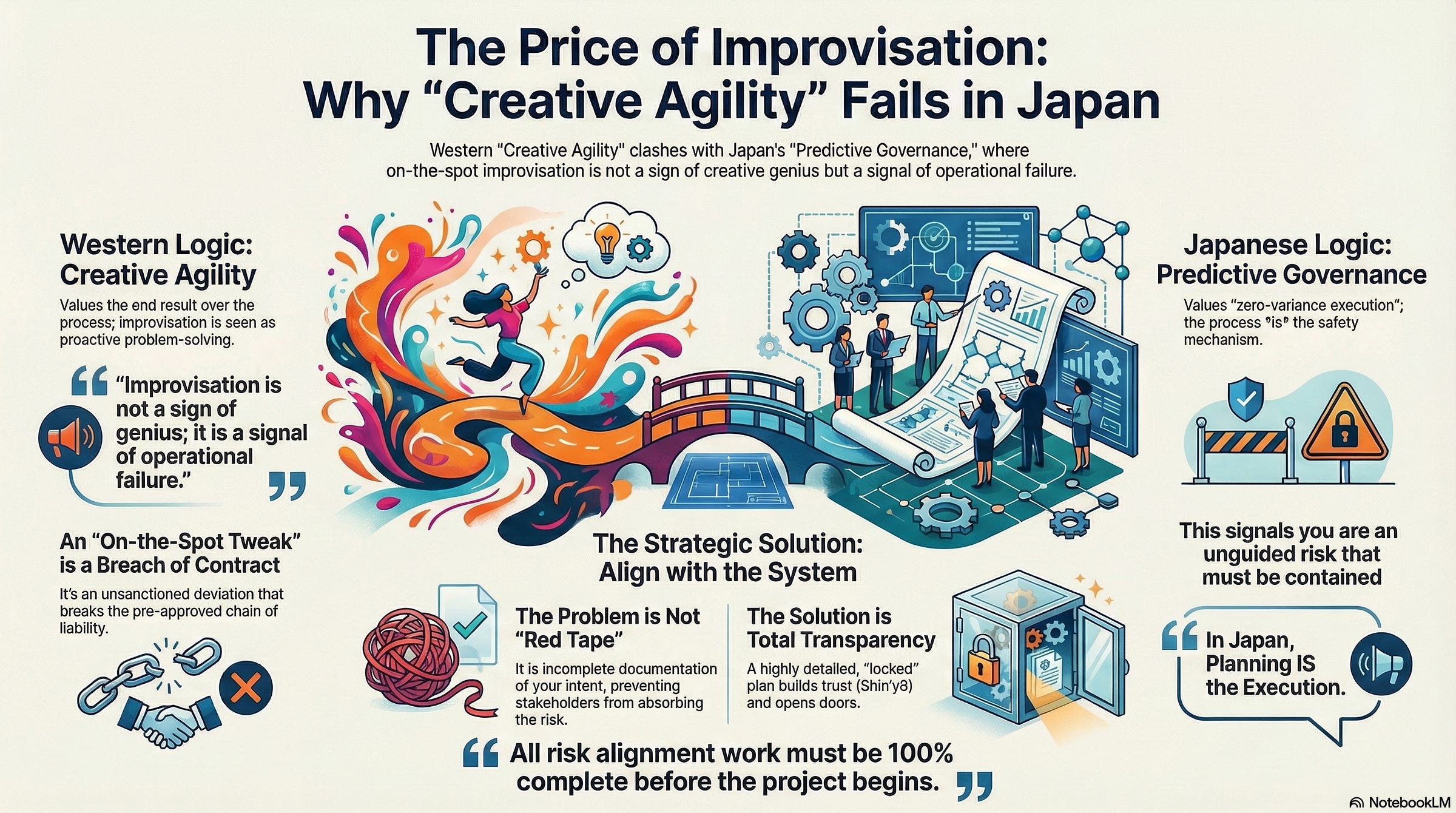

The production hasn’t stalled because of a language barrier. It has stalled because the global team is operating on a logic of “Creative Agility,” while the Japanese environment is built on a logic of “Predictive Governance.” In this market, when you deviate from the plan, you aren’t being “proactive”, you are signaling that you are an unguided risk that must be contained.

The Mechanism: Structural Liability Conflict

This is not a culture issue. This is a Structural Liability Conflict.

Global production teams often operate under the “Ask for Forgiveness, Not Permission” framework. This logic assumes that as long as the end result is high-quality and no one is physically harmed, the process is secondary. In Japan, the process is the safety mechanism. The institutional goal is not “the perfect shot”; it is the “zero-variance execution.”

The Logic of Collective Risk Management

In the Japanese business system, permission is not a transaction between two people; it is a consensus-building exercise among multiple stakeholders. When a location owner grants access, they are vouching for your reliability to their own superiors, neighbors, and local authorities.

The Toyota Parallel: Just as the Toyota Production System (TPS) empowers any worker to pull the “Andon cord” to stop the line when a defect is spotted, the Japanese social system is designed to stop any activity that introduces unplanned variables. Your “on-the-spot” creative decision is seen as a “defect” in the operational plan.

Explicit Responsibility vs. Implicit Agility: In the West, responsibility is often fluid—the producer “figures it out.” In Japan, responsibility must be pinned to a specific, documented individual for every specific action. If a light moves three feet without a prior document, the “Responsibility Chain” is broken.

The Bentley shoot succeeded because the creative intention was not “imposed” on the Japanese environment; it was “translated” into the local governance framework. This required treating every location not as a backdrop, but as a stakeholder engagement. The ryokan, the Fuji terrain, and the Shibuya streets were not “rented”; they were “entered into” via a series of explicit liability transfers.

The Strategic Shift: From Creative Agency to Systemic Predictability

The irreversible insight for any executive overseeing work in Japan is that your “creative vision” is worthless if it cannot be mapped onto a rigid timeline. In most markets, “Planning” is the phase that leads to “Execution.” In Japan, Planning is the Execution. By the time the camera rolls, the “work” of the shoot, the alignment of all risk factors should already be 100% complete.

The Single Irreversible Insight

In Japan, improvisation is not a sign of genius; it is a signal of operational failure.

When a global team arrives with a “we’ll figure it out on the day” mentality, they are unintentionally closing doors. Japanese partners value Shin’yō (trust/credit) above all else. Shin’yō is earned through the demonstration of predictability. If you cannot predict your own movements down to the margin of a sidewalk, you have no Shin’yō, and you will find your access to Japan’s high-contrast, premium environments systematically restricted.

Explicit Reframing: Not Bureaucracy, but Governance

The Problem is not “Red Tape”: It is Incomplete Documentation of Intent. If the Japanese side is saying “No,” it is usually because the “Why” and “How” haven’t been broken down into granular enough steps for them to absorb the risk.

The Solution is not “Flexibility”: It is Total Transparency of Sequence. The more “locked” your plan appears, the more the Japanese system will actually open up to support you.

The Bentley project moved seamlessly across diverse terrains precisely because the “Interpretive Layer”, the local team did not just translate words. They translated Risk Profiles. They prepared the ryokan owners for the visual impact, they secured police alignment for the Shibuya night sequences with zero-margin lighting plans, and they ensured that every “Creative” move had a pre-approved “Operational” counterpart.

Global leaders who fail to account for this “Japan Layer” end up paying a “Chaos Tax”, lost time, burnt relationships, and creative compromises made under the pressure of a stalled schedule. The country rewards those who align with its structure, not those who try to bypass it.

The Bottom Line

Japan is one of the most reliable production environments in the world, provided you accept that your creative freedom is a byproduct of your operational discipline. If you attempt to use “on-the-spot” improvisation as a substitute for exhaustive preparation, the system will prioritize its own stability over your output every single time.

Over to You

Looking at your upcoming projects in Japan, where is “creative flexibility” currently being planned into your schedule as a buffer for incomplete operational alignment?