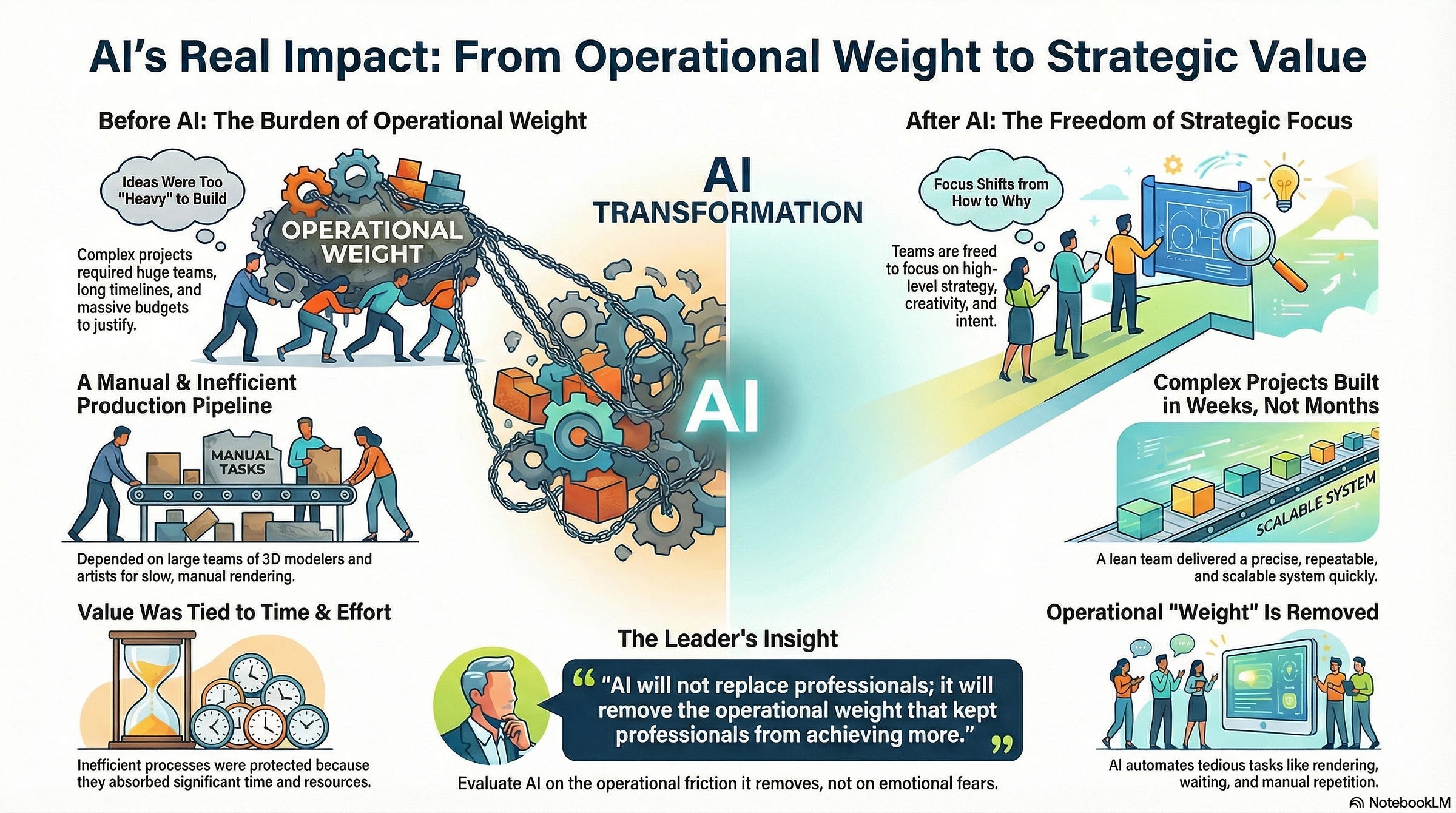

AI resistance grows louder every year. People argue it threatens jobs, lowers quality, or accelerates change faster than organizations can absorb. But when you look closely at how AI functions inside real work, the resistance reveals something far more insightful: people are not pushing back against AI itself—they are pushing back against what AI removes.

The technology rarely touches the core human function of strategic decision-making or creative conceptualization. Instead, it systematically targets and dismantles the expensive, manual, time-consuming buffer that surrounded those strategic tasks. And the XPEL visualizer project is a clear, compelling example of this reality.

The Conversation is Emotional; The Impact is Structural

Most debates surrounding AI remain rooted in the abstract and the emotional. The focus is fixed on disruption, fear, job security, and the catastrophic “replacement” narrative.

But none of these explain what actually happens inside a company when AI is applied to a genuine business problem. The relevant strategic question for any executive is not: “Will AI replace us?” The relevant question is: “What part of our workload disappears when AI is introduced?”

When we built a core tool for the automotive protection film leader XPEL, the answer was immediate and structural.

The Project That Was Too Heavy to Build

XPEL needed an application that could let customers and dealers quickly and accurately visualize their film product on a vehicle. The requirement was clear: an app that allowed users to upload their vehicle, virtually apply the protective film, inspect the finish and coverage, and instantly understand the value proposition.

Before AI, delivering this required an immense production architecture that few companies—even market leaders—could justify:

A large team of 3D modeling specialists for vehicle assets.

Texture artists and manual rendering engines to handle reflections, film layering, and light interaction.

A dedicated development team to manage the complex viewing environment.

A production timeline measured in many months.

A large budget with ongoing, expensive revision cycles.

Significant, heavy cross-departmental coordination overhead.

This is the kind of resource-heavy idea most companies postpone because the cost-to-value ratio is difficult to justify.

AI changed the structure completely. We built the visualizer in weeks, not months. We utilized a lean team, not a full production pipeline. The outputs were precise and repeatable, replacing the hand-rendered compromise of the previous pipeline. Most critically, the system possessed built-in scalability, eliminating the need for future manual rebuilds for every new model or texture.

AI didn’t replace the specialists. It replaced the resource burden—the massive operational overhead—of specialist work.

The Defense of the Buffer

The reason AI triggers resistance is that it fundamentally changes how work is exposed and valued within an organization. It systematically removes the buffer that has historically protected time, inefficiencies, and weak processes.

AI Removes Time-Based Protection: Many historical roles were able to absorb and justify value simply through time investment. AI compresses high-quality output into minutes, dramatically shortening the link between effort and result.

AI Exposes Weak Processes: Workflows built on high-volume repetition, manual data manipulation, or unnecessary steps disappear entirely. What remains visible is only the strategic layer—the conceptual thinking, the audience knowledge, the design intent.

AI Shifts Expectations Upward: When high-quality output becomes cheap and fast, the baseline expectation for human contribution moves upward. People must operate at a higher conceptual level, focusing on why to build something, not how to manually assemble it.

In short, AI doesn’t threaten the professional—the strategic mind or the creative eye. It threatens the parts of the professional’s job that were never truly value-generating to begin with: the waiting, the rendering, the tedious manual repetition. It is the removal of this weight that triggers resistance, because executives and teams are forced to confront the previously hidden cost of their operating inefficiencies.

The Structural Advantage in the Japanese System

This insight is particularly critical for leaders operating in Japan, a market facing unique structural constraints. Japan contends with a shrinking workforce, rising labor costs, slower adoption cycles, and an intense cultural dependency on human precision and quality control.

The resistance to AI in Japan often manifests as a hesitation toward new workflows, a defense of existing manual process, or a deep concern that change will compromise quality. Yet, these are precisely the traits AI excels at supporting.

Japan values: consistency, quality, accuracy, stability, and repeatability.

AI delivers all five more reliably, consistently, and scalably than manual production ever could. Resistance in Japan, therefore, does not protect the integrity of the existing system. It preserves the inefficiencies inside the system—the expensive labor hours spent on tasks that add no strategic value.

The XPEL project produced clarity that is essential for the Japanese context: AI turns complex, resource-heavy ideas into achievable, repeatable systems that inherently deliver the precision and quality the market demands, but without the corresponding operational weight. This is not disruption; this is the necessary infrastructure for long-term productivity and quality maintenance in a structurally constrained economy.

Insight for Leaders

AI changes the executive conversation from capability to allocation. It allows companies to drastically reduce resource load while maintaining or increasing quality at scale. It frees teams from the manual weight of production, shortens timelines, and strengthens precision, fundamentally expanding the scope of what is strategically feasible.

The XPEL app clarifies the real insight for global teams: AI will not replace professionals; it will remove the operational weight that kept professionals from achieving more. That is the structural advantage required to thrive in the demanding, high-standard Japanese market.

The Bottom Line

The fear around AI is emotional and human. The benefits are structural and organizational. Leaders who evaluate AI emotionally will resist it. Leaders who evaluate it operationally—by focusing on the cost of the friction it removes—will adopt it and gain a decisive structural advantage.

Over to You

If you audited your marketing or operations teams today, what is the single biggest “time-based protection” task—a manual step that absorbs significant hours but generates zero strategic value—that AI could eliminate immediately?